Revolutionizing Manufacturing with CNC Machines: Your Ultimate Guide

In today's fast-paced industrial landscape, businesses continuously seek innovative solutions to enhance production efficiency and product quality. Among the groundbreaking technologies shaping modern manufacturing are Computer Numerical Control (CNC) machines. At roc-tech.com, we provide an exclusive range of CNC machines for sale that can transform your production operations.

Understanding CNC Machines

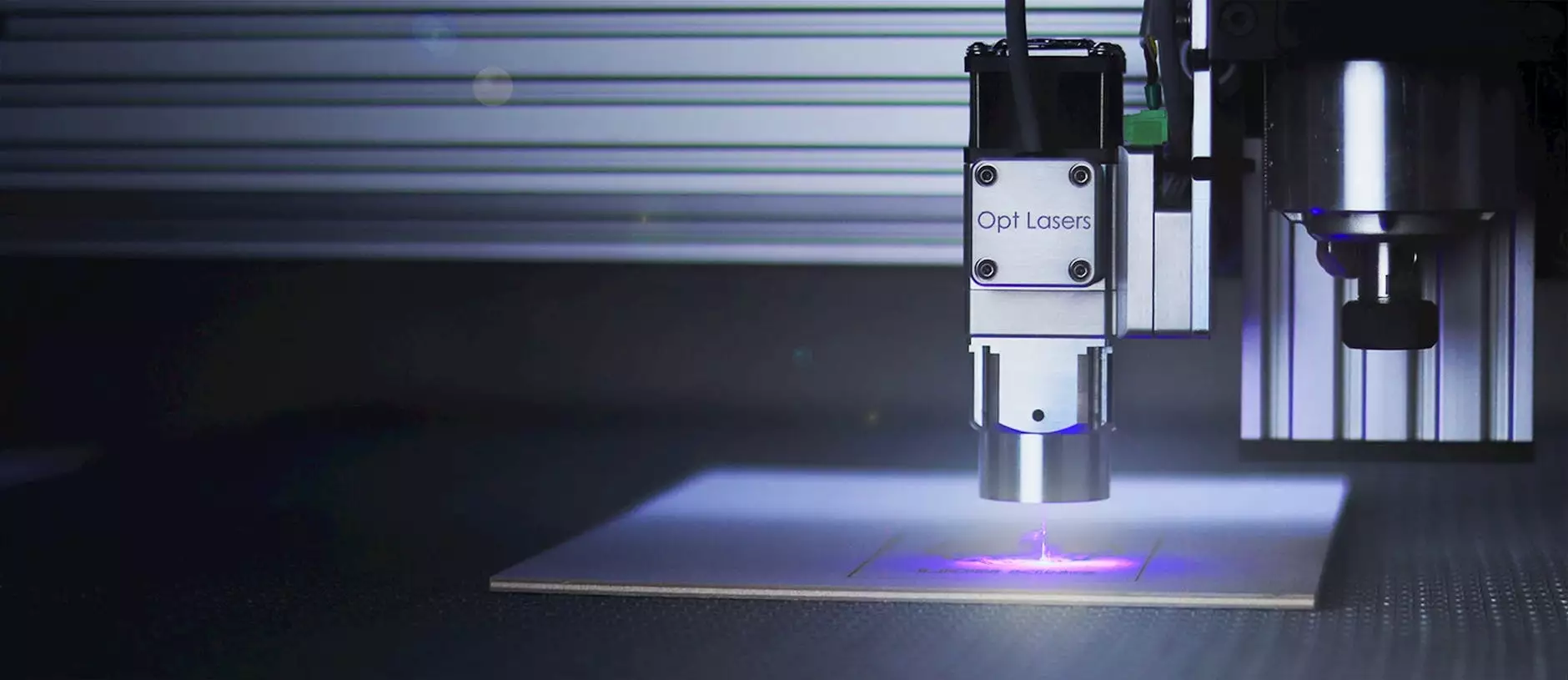

CNC machines are automated tools that use computer programs to control machinery and tools in manufacturing. They are designed to create precise and complex components, which can be made of various materials, including metal, plastic, and wood. The automation offered by CNC technology allows for unmatched consistency and repeatability in production.

The Evolution of CNC Technology

The history of CNC technology dates back to the 1950s, when it was first used for machining tests. Initially, CNC machines were developed to enhance capabilities beyond what was possible with manual machining. As technology advanced, CNC machines have evolved to include various forms, such as milling machines, lathes, and routers, each serving unique applications in the manufacturing process.

Advantages of Using CNC Machines

Here are several pivotal advantages of incorporating CNC machinery into your manufacturing framework:

- Increased Precision and Accuracy: CNC machines can execute complex operations with high precision, which minimizes the risk of human error.

- Enhanced Efficiency: These machines operate continuously, allowing for uninterrupted production and faster turnaround times.

- Consistent Quality: Automation ensures that each piece produced meets the same specifications and quality standards.

- Versatility: CNC machines can perform various operations such as cutting, drilling, grinding, and milling, accommodating a wide range of manufacturing needs.

- Reduced Labor Costs: By automating processes, businesses can reduce the number of operators required on the floor, leading to lower labor costs.

- Safety Improvements: CNC machines minimize direct human interaction with dangerous materials and tools, enhancing workplace safety.

Types of CNC Machines Available at ROC-Tech

At roc-tech.com, we offer a wide selection of CNC machines tailored to meet different manufacturing needs:

CNC Milling Machines

CNC milling machines are widely utilized in the manufacturing industry due to their ability to quickly produce complex shapes. They function by using rotary cutters to remove material from a workpiece as it is fed through the machine.

CNC Lathes

CNC lathes are perfect for producing cylindrical parts. These machines rotate the workpiece on a spindle and use different tools to cut and shape the material.

CNC Routers

CNC routers are versatile machines that can cut, carve, and engrave various materials, making them ideal for woodworking projects and intricate designs.

CNC Plasma Cutters

CNC plasma cutters excel at cutting through metals with high precision and are perfect for businesses that require clean and intricate metal detailing.

How to Choose the Right CNC Machine

Selecting the appropriate CNC machine for your business is crucial. Consider the following factors:

- Material Type: Determine what materials you will be working with (e.g., metals, plastics) to choose a machine designed for that material.

- Precision Requirements: Establish the level of detail needed for your projects, as some machines can offer higher precision than others.

- Budget: Set a realistic budget and explore options within that range, factoring in both initial costs and ongoing maintenance expenses.

- Available Space: Ensure your workshop can accommodate the machine’s dimensions and required operating conditions.

- Manufacturer Support: Opt for brands that offer robust support, maintenance services, and training for operators.

The Future of CNC Technology

As we move deeper into the 21st century, CNC technology continues to evolve. The integration of artificial intelligence (AI), the Internet of Things (IoT), and advanced software is transforming how CNC machines operate. This technology promises improvements in efficiency, enhanced data analytics for predictive maintenance, and even greater adaptability to changing production demands.

Investing in CNC Machines: A Smart Business Move

Investing in CNC technology is not merely about acquiring new tools; it is about future-proofing your business. As industries demand more sophisticated production techniques, having CNC machines from roc-tech.com can place your business at the forefront of innovation.

Meeting Industry Standards

Quality control is integral to manufacturing. CNC machines can help businesses meet regulatory standards by providing precise specifications and reproducible results, which is especially crucial in industries with stringent compliance requirements.

How ROC-Tech Supports Your CNC Journey

At roc-tech.com, we don't just sell CNC machines; we offer comprehensive support to ensure your business thrives:

Expert Consultation

Our experienced team is ready to guide you through the selection process, helping you identify the machine that best fits your operational needs.

Training and Resources

We provide extensive training for your operators and staff to maximize the efficiency and effectiveness of your new CNC machines.

After-Sales Support

Our commitment to our customers extends beyond the sale. We offer ongoing technical support and maintenance services to keep your CNC machines performing at their best.

Conclusion

In conclusion, the adoption of CNC machines, particularly those available at roc-tech.com, is a transformative step towards enhancing productivity and product quality in your manufacturing process. The benefits of precision, efficiency, and scalability offered by CNC technology can significantly impact your business's bottom line. Invest in a CNC machine today and propel your operations into the future of manufacturing.

Contact ROC-Tech to Learn More

For more information on our CNC machines for sale and how they can benefit your business, visit roc-tech.com today. Our team is eager to assist you in transforming your manufacturing capabilities.